Portable Loop Systems

Portable loops – do they ever make sense?

There are two basic types of portable loop, the most common is the one to one portable loop often sold for use at counters or for one to one meetings. The other is much larger and is intended to provide temporary coverage of a hall or meeting room. They are both offered as convenient, low cost alternatives to fixed installations and where used appropriately, they will not disappoint. The key is in understanding their practical and technical limitations.

One to One Portable loops

The one to one portable loop is rechargeable and typically half the size of a briefcase. It will have a built in omni-directional microphone (picks up sound equally from all directions) and loop. The unit is designed to be left on charge, perhaps on its purpose built wall bracket and in theory is always ready.In use, it must be positioned between the two users on a flat surface, such as a counter or desk. The field pattern and uniformity is dependent on the size and orientation of the loop, typically vertical. Smaller loops will exhibit poorer signal uniformity and cover a smaller volume of space. However, even the larger most powerful units will only provide a compliant sweet spot within 400mm or so.

The omni- directional microphone and its positioning are also less than ideal. Hard of hearing people find it difficult to separate the background noise from the wanted signal. Assistive listening systems only work well when they do this for them.They need to filter out the back ground noise and provide a clear intelligible signal to the hearing aid. To achieve this, a directional microphone positioned as close as possible to the person speaking should be used. The omni-directional microphone in the case of the one to one portable loop will pick up much of the background noise, mix it with the wanted speech and deliver this sound cocktail to the hearing aid. Arguably, nothing has been achieved, but if the user had a more capable hearing aid he may actually be worse off.

Regardless of the questionable performance of the typical one to one portable loop systems offered, the practical advantages are also compromised in the most common application. Possibly to save a relatively small amount of money and avoid the inconvenience of installation, one or two portable loops are often purchased to cover a few counters.

This presents some practical issues and is not in the spirit of the old DDA legislation or the current Equalities Act 2010. It is still discriminatory, it is not good for hard of hearing people and it represents a poor deal for the service provider.

Consider the following scenarios; the hard of hearing customer arrives at the counter, there is no fixed loop, he does not want to admit he is disabled, so he tries to engage with the assistant, she explains once, twice, three times, speaking louder and louder, he does not understand, he’s embarrassed, she’s embarrassed and the queue is building. Or, perhaps he does ask to use the portable loop, she leaves the counter, finds the portable loop system, but can’t remember how to use it, she finally gets it working, she’s embarrassed for the delay, he‘s embarrassed for asking and the queue is building.

With a fixed, standard compliant, induction loop system at the counter, the hard of hearing person, would have switched their hearing aid to the T-position, made their transaction at the counter, like anyone else, without any delay, embarrassment or inconvenience, for them, the staff and other members of the public. Everyone would have derived a benefit from the system with customer satisfaction maintained.

The practical and technical limitations of the one to one portable loop system do not mean that it has no place in the market. The better units can be used with an external lapel microphone for improved background noise rejection. They are best suited to applications where portability is fundamental. A mobile location for example, or by visiting professionals such as social and healthcare workers. Portable loops have been used extensively and to good effect in doctor’s surgeries, consultation rooms, hospitals, audiology departments, libraries and in education and social work where the appropriate consideration has been given.

Their poor reputation stems from the overreliance placed on them by many service providers, particularly retailers who view them as a quick, cost effective way of ticking a box and meeting their obligations under legislation when, in fact, for many of the reasons outlined, they provide very little if any benefit to the hearing aid user.

Choosing a one to one portable loop system

A one to one portable loop system will be chosen for its portability, but other parameters must not be overlooked. Use the check list table 1 as a guide.

Choosing a one to One Portable Loop system Check List

| Consideration | Comments |

|---|---|

| Is it small, lightweight and robust? | If it is too small the magnetic field will be too variable and localised (A height and width approx. 300mm is OK, the depth is not important but it must have a firm stable base) |

| Is it easy to carry? | Some units double as a carry case |

| Is there storage space for the charger, an external microphone loop listener and operating instructions? | The accessories need to travel with the loop system for true portability. Remember, it is the gross weight of the system that is important. |

| Is it rechargeable? | Need at least 8 hours use between charge |

| Does it have a battery charge status? | Knowing just how much charge is left in the system is very useful |

| Are the batteries sealed? | There must be no possibility that the batteries could leak |

| What is the battery charger type? | Switch mode battery chargers are smaller and lighter than transformer based chargers |

| Can it deliver a field strength of 400mA/m rms at a distance of 600mm or greater? | The uniformity of the field strength is also an issue. If small movements of the head lead to a dramatic change in field strength, the system will be impractical to use. It is a good idea to check it yourself. |

| What is the operating bandwidth? | It should be at least 100Hz to 5KHz |

| Does it have Automatic Gain Control (Compressor)? | This feature is essential. It Keeps the output level within a comfortable range for the user regardless of the input level |

| Does it have a remote microphone socket? | To get the best out of the system the microphone must be as close as possible to the person speaking, making an external microphone essential |

| Is an external microphone included? | This should form part of the system (not an afterthought |

| Is a loop listener Included? | The user will need some means of checking that the system is working. ( This can be bought separately) |

| Good sound clarity – low distortion? | It must be capable of maintaining good intelligibility. |

| Is the unit clearly marked with hearing logo? | It should be obvious what it is |

| Is there an auto cut off to conserve the battery? | Nice feature, but not essential |

Portable Room Loop Systems

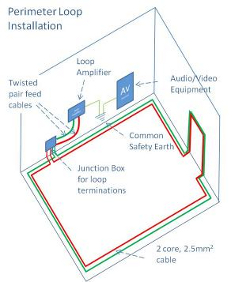

A portable room loop is a complete perimeter loop system in a carry case. The case, typically a flight case has a loop amplifier built in and is supplied with a loop cable and at least 1 microphone as standard. In addition it should include a loop listener/tester since, with each deployment of the system, some adjustment to the output will be required if the performance standard is to be met.

It can provide a cost effective, quick fix, temporary or possibly permanent solution to hearing accessibility satisfying the Equalities Act 2010 and similar legislation worldwide.

If you manage several small to medium size meeting rooms that are rarely used or you travel to different venues to deliver presentations, then a portable room loop is a practical, permanent solution. However if you have one or more meeting rooms that are constantly in use then the portable room loop should probably be viewed as a short term solution, perhaps until there is sufficient budget to make fixed installations and the rooms are due for refurbishment.

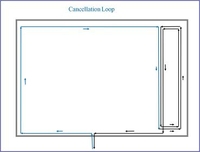

With a fixed installation, the loop is always there and hopefully, always on. Whilst a well-designed portable system will not take long to deploy and set up, it does require continuous management, which over time will add considerable cost and irritation to the business. Furthermore, a portable room loop uses a perimeter loop, this has a significant spill field meaning that 2 or more systems cannot be used in adjacent rooms simultaneously and it is unsuitable for confidential meetings. In addition, the loop performance can be restricted by constructional metal in the building. A SuperLoop system, a special type of induction loop system, overcomes all of these issues, but it must be installed.

Choosing a portable room loop

To select the most appropriate portable loop system for your venue you need to understand where and how the system will be used.

The Rooms

The sizes of the different rooms that the system will be used in provide a guide to just how powerful the system needs to be. Ideally, the system will be capable of covering the whole area of the largest room, but in any event, no less than 30% of the space should be covered as a guide.

| ROOMS | Comments | Notes |

|---|---|---|

| How many locations will the portable room loop be used in? | If it will be used in several rooms that are in frequent use you may need more than one system? | |

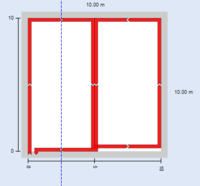

| How big are the rooms? | Choose a system that is capable of covering at least 30% of the largest space. | L = ………… W=……… A=……….. |

The actual area coverage that a loop system can achieve will be reduced by the amount and type of metal in the floor construction as metal absorbs the signal.

Use the pictures below to help identify the type of building or floor construction where the system will be used.

The de-rating factors given are only valid for Univox® Amplifiers. Other manufacturers should be able to provide similar data.

1. Non-metallic e.g. wood or stone

Area Coverage does not need to be de rated as there are no losses. (Area coverage for the Univox® PL-2 = 150m2 )

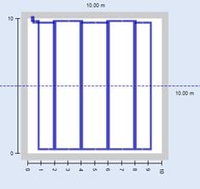

Max loop width =20m. This assumes the loop is laid on the floor and the listening height is at 1.2m from the ground. If this width is exceeded, the signal strength in the middle of the room will be lower than the standard permits

2.Standard reinforced concrete

De-rate area coverage by 20% to compensate for signal loss (Area coverage for the Univox® PL-2 approx. 120m2)

Maximum loop width = 5m to 7m. If this width is exceeded, the signal strength in the middle of the room is likely to be lower than the performance standard permits and metal loss or tone control will not be capable of providing uniform compensation over the whole space

3. Heavy reinforced concrete

De rate are coverage by 30% (Area coverage for the Univox® PL-2 approx. 105m2)

Maximum loop width = 5m If this width is exceeded, the signal strength in the middle of the room is likely to be lower than the performance standard permits and metal loss or tone control will not be capable of providing uniform compensation over the whole space

4. Metal Raised Access Floor

De rate are coverage by 50% (Area coverage for the Univox® PL-2 approx.75m2)

Maximum loop width = 4m. If this width is exceeded, the signal strength in the middle of the room is likely to be lower than the performance standard permits and metal loss or tone control will not be capable of providing uniform compensation over the whole space

5. Metal System Floor

De rate are coverage by 50% (Area coverage for the Univox® PL-2 approx.75m2)

Maximum loop width = 4m. If this width is exceeded, the signal strength in the middle of the room is likely to be lower than the performance standard permits and metal loss or tone control will not be capable of providing uniform compensation over the whole space

6. Glass and metal construction

De rate are coverage by 50% (Area coverage for the Univox® PL-2 approx.75m2)

Maximum loop width = 4m. If this width is exceeded, the signal strength in the middle of the room is likely to be lower than the performance standard permits and metal loss or tone control will not be capable of providing uniform compensation over the whole space

The maximum loop widths given are indicative and valid for any perimeter loop system.

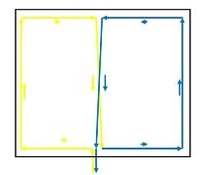

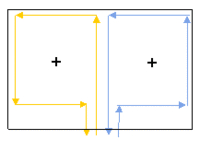

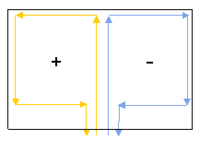

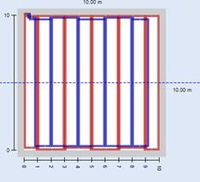

Note: By laying the loop cable in a figure 8 pattern, the maximum loop width can be maintained for larger spaces.

Background Magnetic Noise

An induction loop system will not provide a benefit to hard of hearing people where the level of background magnetic noise is too high. Where possible, check the level of background magnetic noise in each of the intended locations for the portable loop system before purchase. (It should be less than -32dBA) UnivoxAudio and our partners will be pleased to help.

How Are the Rooms Used

To specify the appropriate accessories for the portable loop system it is necessary to understand how the rooms are used and what, if any, audio visual equipment is used in each. If there is a sound reinforcement system in each of the rooms, check that they have line level outputs which are easy to access. In this case, additional microphones may not be necessary. However, the Portable loop system will need at least 1 line level input and a suitable interconnecting. Where none or only some rooms have sound reinforcement, microphones must be specified with the portable loop system. In which case consider the following;-

- Do the presenters stand in one place?

A wired microphone may be suitable

- Do the presenters move around the room or present from different locations in the room?

A radio microphone may be the most practical. You can choose a held or headset/lapel type. Note: Holding a microphone for any length of time can be fatiguing

- Is audience participation required?

A second radio microphone may be required. A hand held microphone is the most appropriate for this purpose.

- Are there any other audio sources such as a DVD player or television in any of the rooms?

Check that the line output from the source(s) is easy to access. The Portable loop system will need a spare line input to make this connection.

Portable Room Loop product Check List

Use the check list (table 3) to guide you to your optimum Portable Induction Loop system.

Portable Room Loop product Check List (Table 3)

| Consideration | Comments |

|---|---|

| What is the Square Area Coverage of the system? | Is the square area coverage of the system sufficient for your rooms and building construction? |

| Is the case small, lightweight and robust? | There should be a dedicated space for each piece of equipment and accessory in the case. This makes it easier to check that everything has been packed away. It also keeps everything tidy and well protected. |

| Will it be easy to carry? | A flight case with wheels is a good practical option. Remember, it is the gross weight of the system that is important |

| What power supply is required? | For use in the UK 230V ac operation is required |

| Is the amplifier built into the case? | With the loop amplifier built into the case, the system will be much quicker to set up. Some systems are simply standard amplifiers offered in a carry case |

| Are the controls, inputs and outputs easy to access? | Important for ease and speed of setup |

| How many line and microphone inputs are there? | Refer to the section ‘How are the rooms used’ to confirm what inputs are required. Ideally, the inputs will be balanced to provide better immunity to electrical interference. |

| What is the operating bandwidth? | To meet the performance standard IEC60118-4 it should be no less than 100Hz to 5KHz |

| Does it have Automatic Gain Control (Compressor) | This is an essential feature. It keeps the output level within a comfortable range for the user regardless of the input level |

| What length is the loop cable and how is it stored? | The loop cable should be wound on a spool with both endsterminated in a plug. This will keep the cable tidy and protected when not in use. It will also facilitate quick deployment and retrieval. For best performance the cable should be non-inductively wound on the spool. This helps to maintain the frequency response of the system when operated with some cable still on the spool. |

| Accessories | To get the best out of the system the microphone must be as close as possible to the person speaking, making an external microphone essential |

| How many microphones are required? | Refer to the section ‘How are the rooms used’ to confirm how many and what type of microphones will be most suited. It is advisable to include at least 1 |

| Is a battery charger included? | If you choose wireless microphones, a suitable battery charger should be included with the system |

| How do I check the field strength? | A loop Listener/field strength indicator must be included with the system |

| What consumables are required? | None, however, it is good practice to tape the loop to the floor to prevent it from becoming a trip hazard.Gaffer tape provides a practical solution. |

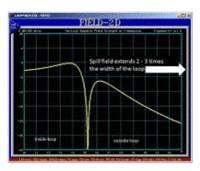

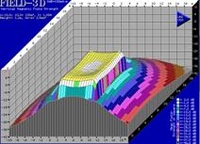

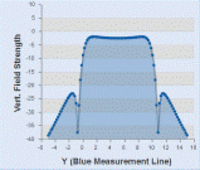

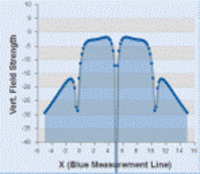

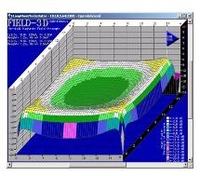

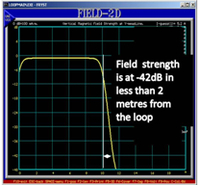

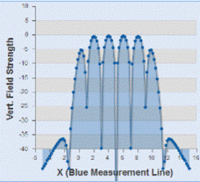

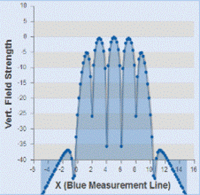

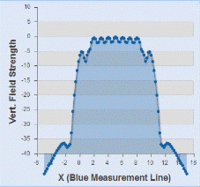

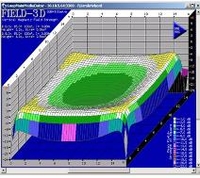

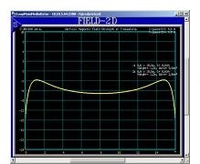

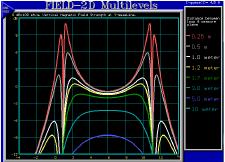

The graph on the right shows the variation of field strength across the centre of a room at a range of listening distances from a perimeter loop. The red curve shows the field strength at a vertical distance of 0.25m from the loop.

The graph on the right shows the variation of field strength across the centre of a room at a range of listening distances from a perimeter loop. The red curve shows the field strength at a vertical distance of 0.25m from the loop.